Send a message.

We’re here to answer any question you may have.

OPTİTUR MARİN

T: +90 216 491 48 48

M. +90 538 085 1808

info@opti-tur.com

We’re here to answer any question you may have.

T: +90 216 491 48 48

M. +90 538 085 1808

info@opti-tur.com

info@opti-tur.com

Bir sorunuz mu var? Cevaplamak için buradayız.

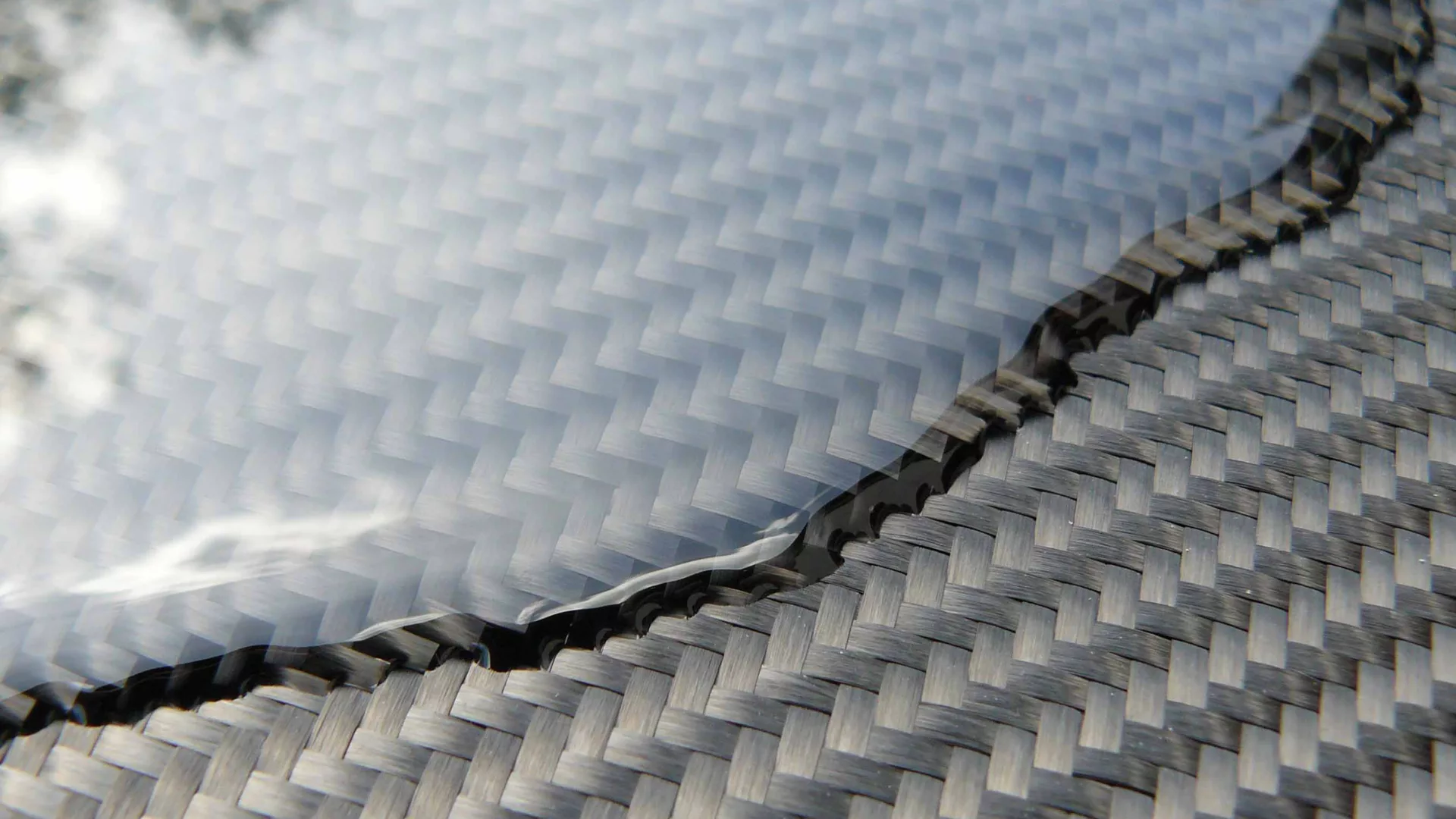

Optitur Marin was founded in 2015 with the aim of producing advanced carbon-composite parts.

Vacuum Infusion is an advanced manufacturing method used in composite part production. This technology is developed to produce high-strength, lightweight, and durable composite materials.

Advantages of Vacuum Infusion

It creates a stronger bond between the fiber and resin, providing superior mechanical properties.

Using less resin results in lighter parts.

The vacuum infusion process allows for a smooth and aesthetically pleasing surface finish.

It causes less harm to the environment with low VOC (volatile organic compound) emissions.

Hand Lay-Up is a traditional manufacturing method used in composite part production. This process involves manually placing reinforcement materials, such as fiberglass and carbon fiber, into a mold and applying resin over them.

It offers high production flexibility for small-scale and complex designs.

It provides a cost advantage in small production volumes, particularly due to lower mold costs.

As a manual method that requires simple equipment, it speeds up the production process.

By manually adjusting the resin and fiber ratios, it is possible to achieve the desired strength and weight values.

Closed Mold Resin Transfer (RTM) is a closed mold method used in composite part production. Resin is injected into a closed mold where the fibers are placed under low pressure. RTM is frequently preferred in industries such as automotive, aerospace, energy, and maritime for the production of lightweight and strong parts.

The closed mold system ensures that parts have a smooth surface finish.

High precision control is achieved over resin flow and thickness.

It is suitable for mass production processes, providing cost and time savings.

It is a flexible method that can be applied with different materials and molds.

Thanks to the closed system, environmentally friendly production with low VOC emissions and minimum waste is achieved.

Adding {{itemName}} to cart

Added {{itemName}} to cart